Cathelco are world leading designers and manufacturers of equipment for ships and offshore installations. Cathelco product range includes marine pipework anti-fouling (AF) systems and impressed current cathodic protection (ICCP) systems to safeguard the hulls of commercial and naval vessels against corrosion. These ICCP systems also provide flexible yet comprehensive protection for offshore platforms, rigs, wind turbines, semi-submersibles, FPSO & FSO’s.

ICCP System:

HOW DOES AN ICCP SYSTEM WORK?

Although modern hull coatings provide some protection against corrosion they do not offer a complete solution. For this reason, most operators choose to protect their vessels with a purpose designed impressed current cathodic protection system.

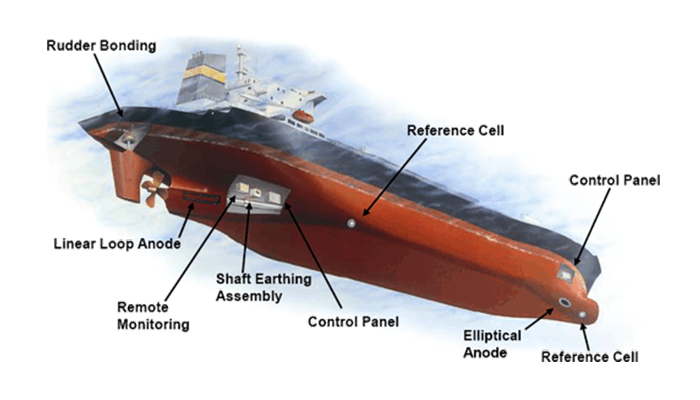

Using an arrangement of hull mounted anodes and reference cells connected to a control panel(s), the system produces a more powerful external current to suppress the natural electro-chemical activity on the wetted surface of the hull.

This eliminates the formation of aggressive corrosion cells on the surface of plates and avoids the problems which can exist where dissimilar metals are introduced through welding or brought into proximity by other components such as propellers.

The systems are designed to automate the current output while the voltage output is varied. This allows the protection level to be maintained as the seawater resistivity alters. In a sacrificial anode system, increases in the seawater resistivity can cause a decrease in the anode output and a decrease in the amount of protection provided. With ICCP systems protection does not decrease in the range of standard seawater.

An essential feature of ICCP systems is that they constantly monitor the electrical potential at the seawater/hull interface and carefully adjust the output to the anodes in relation to this. Therefore, the system is much more effective and reliable than sacrificial anode systems where the level of protection is unknown and uncontrollable.

Pipework Antifouling and Anodes solutions

AF SYSTEMS FOR COMMERCIAL VESSELS

Cathelco’s reputation has been built on providing seawater pipework anti-fouling systems for some of the largest fleets of commercial vessels in the world.

With the ability to treat high volumes of sea water, the system is ideally suited to the requirements of the VLCCs, container ships, LNG carriers and numerous other types of ocean going vessels.

For this reason, it continues to be chosen by major operators, reflecting both the effectiveness of the system and the on-going support which is provided to customers.

In operation, the system is automatic and makes very little demands on crew time apart from periodically monitoring the anode outputs. A log sheet monitoring service provided by Cathelco ensures that systems continue to perform effectively.

Modular control panels and anodes

Economical and compact in design, modular control panels

are easy to install. Read more

A range of anodes and mounting types are available

for commercial vessels. Read more

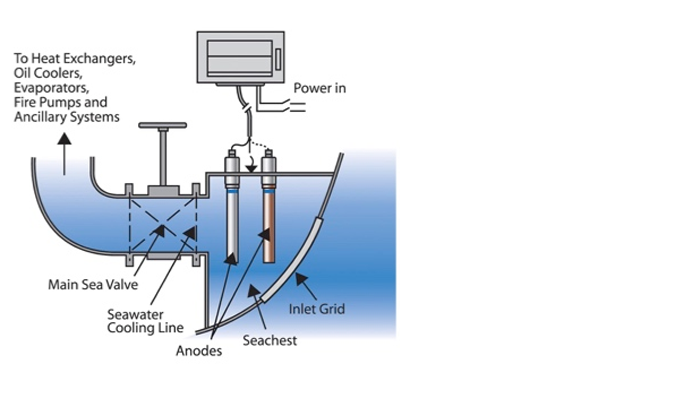

Seachest anode installations

When systems are installed at newbuilding, anodes are generally fitted in the seachests using special sleeves or flange mountings.

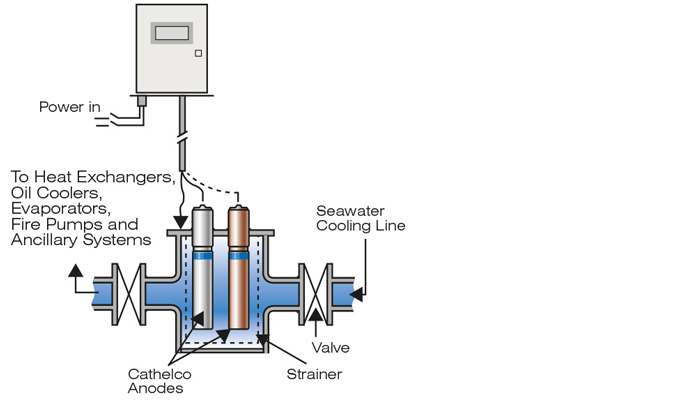

Strainer mounted anodes

If systems need to be installed prior to scheduled drydocking, the anodes can be mounted in the seawater strainers. This also simplifies replacement when anode renewal becomes necessary.

Copper Anodes, Aluminium Anodes, Linear Anodes, Dual Purpose Anodes, Ferrous Anodes, Omni Anodes, Ferrous Anodes, Reference Electrodes and Cathodes also available.

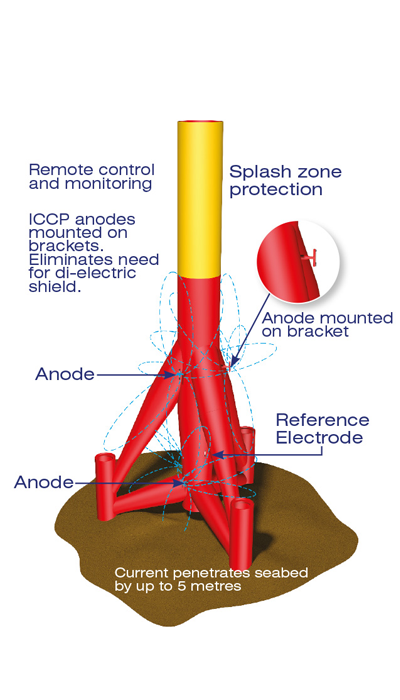

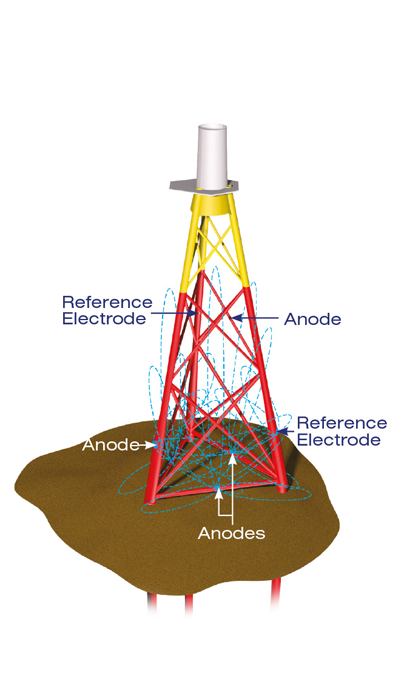

MAJOR FEATURES OF THE CATHELCO WIND TURBINE ICCP SYSTEM

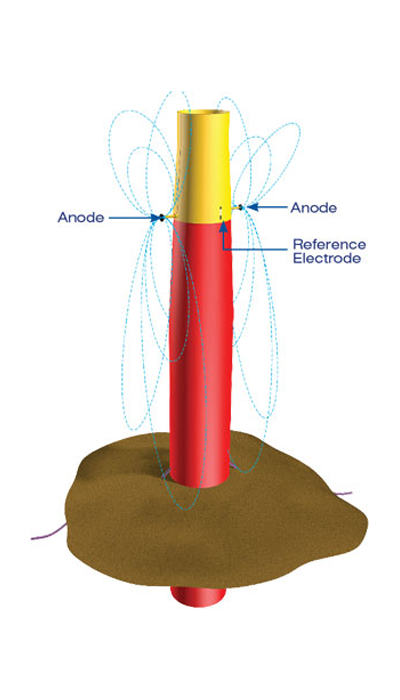

Greater flexibility

By mounting the anodes and reference electrodes externally, the problems associated with traditional cofferdam installations are eliminated.

Expert system design

Using Cathelco’s background of expertise systems can be designed to protect the complex geometry of tripod and jacket structures.

Small anode footprint

The tubular design of the ICCP element results in a very compact anode which combines a small footprint with a high current output.

Optimum anode distribution

Greater access means that anodes can be positioned to achieve the optimum current distribution without the risk of ‘shading’.

Easier installation

Anodes and reference electrodes are fitted using ‘self-torquing’ fastenings.

Control and data monitoring

The system can be remotely controlled using Cathelco’s software and monitored via the Internet.

CATHELCO SEAFRESH REVERSE OSMOSIS DESALINATORS

Reliable technology with worldwide service support

Seafresh have been designing and manufacturing desalinators for more than 30 years. The desalinators are based on reverse osmosis technology, a well-established and reliable method of turning sea water into potable water.

The range includes the H20 Series with outputs from 36 to 276 liters per hour and the Ton Series which can produce 10 to 40 cubic meters of fresh water per day.

The award winning Seafresh designs have gained a reputation for reliability, durability and ease of operation on more than 1,800 craft around the world. These include installations on all types of small commercial craft including ferries, research vessels, offshore supply vessels, tugs and fishing craft. In addition, the company has supplied equipment for the surface craft and submarines of more than 40 navies.

Cathelco Seafresh desalinators are also widely used on luxury yachts and are specified by world renowned builders such as Discovery and Oyster.

Now a division of Cathelco – a world leading name in marine equipment – Seafresh benefits from an international sales and service network putting the advice and experience of fully trained personnel at your disposal for installation and servicing.

For more information, contact us or visit the Cathelco Seafresh website – click here